The Story Behind Magnepan

Magnepan has been manufacturing innovative, world class stereo speakers for 47 years. Jim Winey, the inventor of the Magneplanar loudspeaker, first owned electrostatic loudspeakers and began experimenting to design an improved electrostatic speaker. In 1969, Jim invented the Magneplanar, a thin-film magnetic equivalent to the electrostat and founded Magnepan. Corporate and manufacturing facilities are located in White Bear Lake, Minnesota, a small community north of the Twin Cities of St. Paul and Minneapolis. Having outgrown its original facilities, Magnepan’s current plant is over 50,000 square feet in addition to corporate and engineering offices. To date, over 200,000 pairs of Magneplanar loudspeakers have found their way into the homes of music lovers the world over. Magneplanars are American-made with virtually all American parts. And we are proud to say— “Made in America. Sold in China.”

A glimpse into the handcrafting required to build your pair of Magneplanars.

Above

CNC mill cutting MDF panel

Right

Completed CNC milled panel ready for the next step

The Wood Shop

Starting in the wood shop, where the panel frames are formed on a numerically controlled machine. Those frames begin life as a quotidian sheet of trusty MDF; dimensionally stable, homogeneous in all three dimensions, and inexpensive.

Above

Magnet Assembly

Right

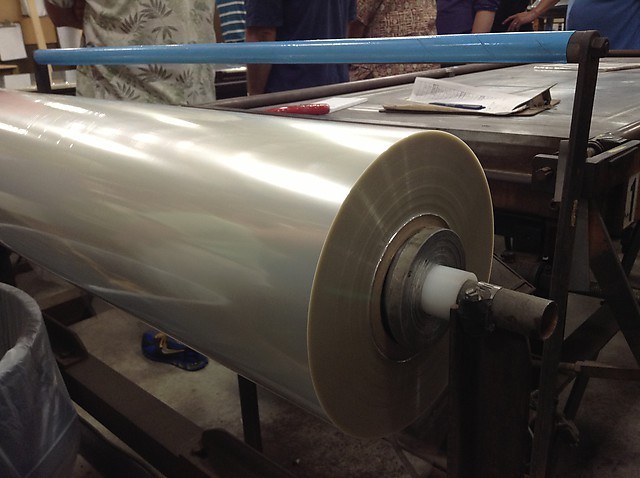

Raw Mylar film ready to be attached to the panels

Magnet Assembly

To create a “voice coil,” you need a former. Traditional loudspeakers use circular or square cross-section wire wrapped around a cylindrical former. Magneplanars use something akin to more modern printed voice “coils” sometimes used in tweeters. Instead of wire, a very, very thin aluminum strip is attached, by hand, to Mylar film. When placed in proximity of the magnets, this drives the entire surface of the film. Mylar is also dimensionally stable and not hygroscopic which assures proper tension across the frame.

Above

Finished panel with “buttons” installed

Right

True magnetic ribbon assembly

True Magnetic Ribbon

Magnepan offers this true ribbon in their high-end tweeters, two good examples being their 3.7 three way and their Mini Maggie 2.1 system. Great sound at what could also be called an insane price. In fact, that sums up their entire range…neutral voicing, excellent transient response, room filling with a wide sweet spot considering they are panels, and prices that make one laugh at the idea of domestically (hand) made goods generally being on the spendy side.

Finished Panel

The buttons “…break up the diaphragm into multiple resonant areas.” As you probably know, electromechanical systems exhibit resonances as do purely mechanical and electronic systems. EQ is a common example of electrical resonance. The simpler the system, the easier it is to predict the resonant modes. By the way, resonance, according to Wikipedia is the “tendency of a system to oscillate with greater amplitude at some frequencies than at others.” Think guitar string. Imagine a Maggie at resonance, that large expanse of plastic flopping around excessively, it’s liable to bottom out with some resulting nasty distortion. Hence the buttons, which detune the panel and reduce the effects of resonances. Though most of Magnepan’s products are quasi–ribbon, they also make true ribbons in the old school sense; a corrugated strip of aluminum, vanishingly thin, suspended in a magnetic field:

A Tradition of Innovation and Advanced Technology

Box enclosure vs. Free space

Power Response

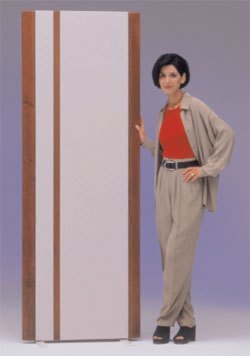

A small box speaker sitting on the floor will not create a convincing sound stage.

This problem can be partially corrected by placing the box speaker on a tall speaker stand.

But, something is still lacking. One of the problems is lack of power response.

Power response is a little-understood aspect of a loudspeaker’s performance.

Ideally, the energy from a loudspeaker should measure the same at any microphone position in the room.

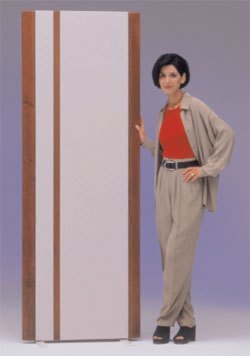

A very narrow, floor-to-ceiling line source driver provides the best power response and the most realistic sound.

The tall line source driver of a Magneplanar provides a better sense of “you are there”.

Theoretically, loudspeakers should use massless drivers suspended in free space with no box,

magnet structure, or framework around the drivers.

Most conventional box speakers are far from this ideal.

The mass of the driver is high and the rear wave is contained within the box or magnet structure.

While the frequency response can be smoothed out in a box speaker, the character of the sound is inevitably affected.

In the worst cases, the music sounds like it is coming out of a box-constricted and unnatural.

The Magneplanar diaphragm comes closer to the ideal driver.

The mass is low and the diaphragm is not contained.

The rear sound wave is not restricted and radiates freely into space.

With the box removed, Magneplanars sound more like you are there.

Uniform Drive

The conventional dynamic driver struggles with a dual requirement–

The mass should be low so the driver can accurately follow the electrical signal.

But, the driver should be very stiff so all of the driver moves together.

Zero mass and infinite stiffness are mutually exclusive.

This dual requirement has been the driving force behind innovative solutions to address these problems.

Ribbon and electrostatic speakers side-step this problem by eliminating the need for stiffness.

The ribbon or thin film is driven over its entire area. Stiffness is irrelevant so the designer can focus on low mass.

Mass

Electrons from an amplifier move at the speed of light.

If only loudspeakers could move with the same speed.

Thin-film loudspeakers are as close to zero mass as is physically possible.

Even a subtle “breath of air” from the amplifier will cause the low mass ribbon to respond.

Magneplanars use ultra low mass, thin film ribbon drivers.

For example, the Magneplanar true ribbon element is 1/10 the thickness of a human hair.

It is so light that when a piece of it is dropped from a height of 6 feet it takes an average of 5 seconds for it to reach the floor.

Conventional speaker designs prohibit such low mass.

The force from the amplifier would destroy conventional speakers made of such light materials.

Only by driving the transducer over its entire area can materials of such low mass be used.

Quasi Ribbon Driver

The quasi ribbon driver is a variation on the original true ribbon design.

The true ribbon, as shown below, is a very simple device.

The ultra-thin aluminum foil carries the current from the amplifier and is also the means of moving the air to create sound.

No voice coil. No cone. No surround. No box. Nothing except the ribbon.

The quasi ribbon is ANY variation from the original true ribbon—and there are many.

The Magneplanar quasi ribbon is simply a true ribbon on a mylar film.

This design is very rugged and cost-effective with very wide bandwidth.

Many of the best high-end headphones use planar magnetic quasi ribbon drivers.

You will recognize the sonic similarity of a Magneplanar and planar magnetic quasi ribbon headphones.

Both the Magneplanar true ribbon and quasi ribbon drivers eliminate the need for a transformer—nothing between the amplifier to degrade the sound.

Ribbon drivers are non-reactive and act like a simple resistor to the amplifier. While Magneplanars do require an amplifier with the ability to drive a 4 ohm load, the non-reactive load will allow an amplifier to perform at its best.

True Ribbon Tweeter: The finest ribbon tweeter in the world!

The Magneplanar direct-coupled ribbon tweeter has no equal in high frequency sound reproduction.

With its 360 degree radiating dipole design, the Magneplanar ribbon tweeter is found in our award winning 3.7i and 20.7 speakers.

At 1/10th the thickness of a human hair, the Magneplanar ribbon tweeter sets a standard for high resolution. You’ll find yourself hearing details in the music you never heard before.

Audiophile reviewers have long regarded the Magneplanar true ribbon tweeter as the best on the market.

You can be the final judge.

Compare the Magneplanar true ribbon against the most expensive dynamic speakers on the market.

Bass accuracy and full-range dipole speakers

Full-range planar (electrostatic or ribbon) speakers have a reputation with audiophiles for uncanny bass and midbass accuracy.

There are practical considerations that preclude the widespread use of planar technology for bass and midbass reproduction,

but these large and expensive full-range dipoles can reproduce the correct timbre of an acoustical bass instrument that is smeared with conventional woofers in hybrid designs.

A full-range planar speaker can reproduce the lower register of a piano with the same resolution as the midrange.

There is no sense of a woofer altering the sound of a piano.

To put it another way, a woofer in a box has a characteristic sound that puts its “signature” on all bass instruments.

It may not matter when listening to electronic bass instruments, but once you have heard acoustical bass instruments reproduced on a full-range dipole, it’s hard to forget!

The Magneplanar is the only full-range dipole that offers bass and midbass definition at a reasonable price, size, and reliability never before achieved from any other full-range dipole.

Have you carefully listened to the bass? We are hoping you will.

Once a listener develops an appreciation for dipole sound, few go back to conventional dynamic speakers.

Box enclosure vs. Free space

Power Response

A small box speaker sitting on the floor will not create a convincing sound stage. This problem can be partially corrected by placing the box speaker on a tall speaker stand. But, something is still lacking. One of the problems is lack of power response.

Power response is a little-understood aspect of a loudspeaker’s performance. Ideally, the energy from a loudspeaker should measure the same at any microphone position in the room. A very narrow, floor-to-ceiling line source driver provides the best power response and the most realistic sound. The tall line source driver of a Magneplanar provides a better sense of “you are there”.

Theoretically, loudspeakers should use massless drivers suspended in free space with no box, magnet structure, or framework around the drivers. Most conventional box speakers are far from this ideal. The mass of the driver is high and the rear wave is contained within the box or magnet structure. While the frequency response can be smoothed out in a box speaker, the character of the sound is inevitably affected. In the worst cases, the music sounds like it is coming out of a box-constricted and unnatural.

The Magneplanar diaphragm comes closer to the ideal driver. The mass is low and the diaphragm is not contained. The rear sound wave is not restricted and radiates freely into space. With the box removed, Magneplanars sound more like you are there.

Uniform Drive

The conventional dynamic driver struggles with a dual requirement– The mass should be low so the driver can accurately follow the electrical signal. But, the driver should be very stiff so all of the driver moves together. Zero mass and infinite stiffness are mutually exclusive.

This dual requirement has been the driving force behind innovative solutions to address these problems. Ribbon and electrostatic speakers side-step this problem by eliminating the need for stiffness. The ribbon or thin film is driven over its entire area. Stiffness is irrelevant so the designer can focus on low mass.

Mass

Electrons from an amplifier move at the speed of light. If only loudspeakers could move with the same speed. Thin-film loudspeakers are as close to zero mass as is physically possible. Even a subtle “breath of air” from the amplifier will cause the low mass ribbon to respond.

Magneplanars use ultra low mass, thin film ribbon drivers. For example, the Magneplanar true ribbon element is 1/10 the thickness of a human hair. It is so light that when a piece of it is dropped from a height of 6 feet it takes an average of 5 seconds for it to reach the floor. Conventional speaker designs prohibit such low mass. The force from the amplifier would destroy conventional speakers made of such light materials. Only by driving the transducer over its entire area can materials of such low mass be used.

Quasi Ribbon Driver

The quasi ribbon driver is a variation on the original true ribbon design. The true ribbon, as shown below, is a very simple device. The ultra-thin aluminum foil carries the current from the amplifier and is also the means of moving the air to create sound. No voice coil. No cone. No surround. No box. Nothing except the ribbon.

The quasi ribbon is ANY variation from the original true ribbon—and there are many. The Magneplanar quasi ribbon is simply a true ribbon on a mylar film. This design is very rugged and cost-effective with very wide bandwidth. Many of the best high-end headphones use planar magnetic quasi ribbon drivers. You will recognize the sonic similarity of a Magneplanar and planar magnetic quasi ribbon headphones.

Both the Magneplanar true ribbon and quasi ribbon drivers eliminate the need for a transformer—nothing between the amplifier to degrade the sound. Ribbon drivers are non-reactive and act like a simple resistor to the amplifier. While Magneplanars do require an amplifier with the ability to drive a 4 ohm load, the non-reactive load will allow an amplifier to perform at its best.

True Ribbon Tweeter: The finest ribbon tweeter in the world!

The Magneplanar direct-coupled ribbon tweeter has no equal in high frequency sound reproduction. With its 360 degree radiating dipole design, the Magneplanar ribbon tweeter is found in our award winning 3.7i and 20.7 speakers. At 1/10th the thickness of a human hair, the Magneplanar ribbon tweeter sets a standard for high resolution. You’ll find yourself hearing details in the music you never heard before.

Audiophile reviewers have long regarded the Magneplanar true ribbon tweeter as the best on the market. You can be the final judge. Compare the Magneplanar true ribbon against the most expensive dynamic speakers on the market.

Bass accuracy and full-range dipole speakers

Full-range planar (electrostatic or ribbon) speakers have a reputation with audiophiles for uncanny bass and midbass accuracy. There are practical considerations that preclude the widespread use of planar technology for bass and midbass reproduction, but these large and expensive full-range dipoles can reproduce the correct timbre of an acoustical bass instrument that is smeared with conventional woofers in hybrid designs.

A full-range planar speaker can reproduce the lower register of a piano with the same resolution as the midrange. There is no sense of a woofer altering the sound of a piano. To put it another way, a woofer in a box has a characteristic sound that puts its “signature” on all bass instruments. It may not matter when listening to electronic bass instruments, but once you have heard acoustical bass instruments reproduced on a full-range dipole, it’s hard to forget! The Magneplanar is the only full-range dipole that offers bass and midbass definition at a reasonable price, size, and reliability never before achieved from any other full-range dipole. Have you carefully listened to the bass? We are hoping you will. Once a listener develops an appreciation for dipole sound, few go back to conventional dynamic speakers.